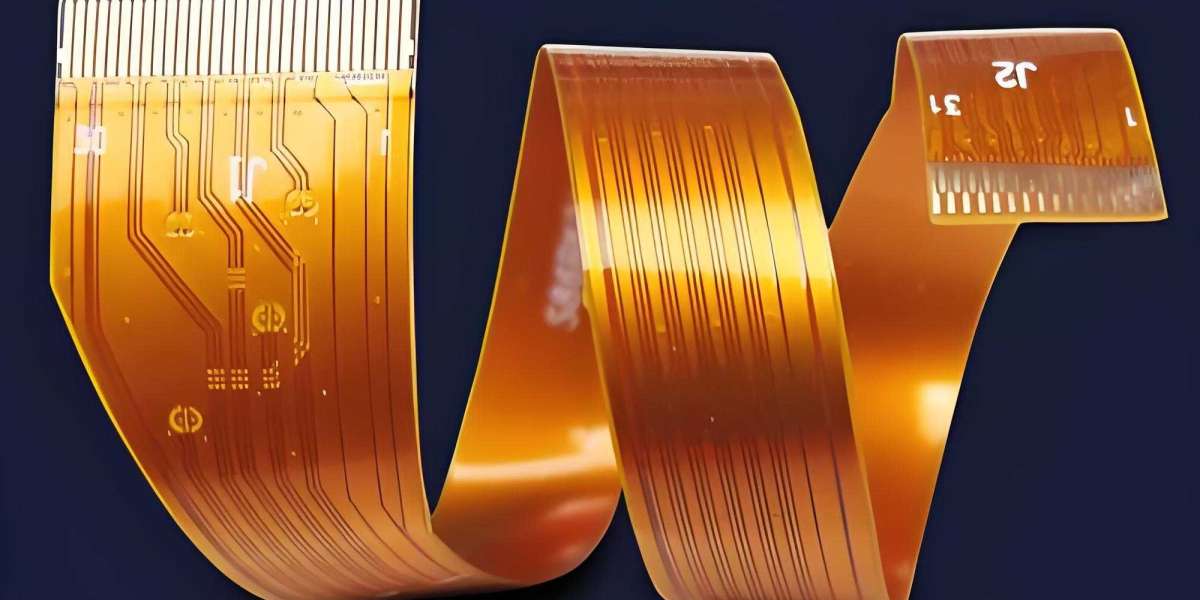

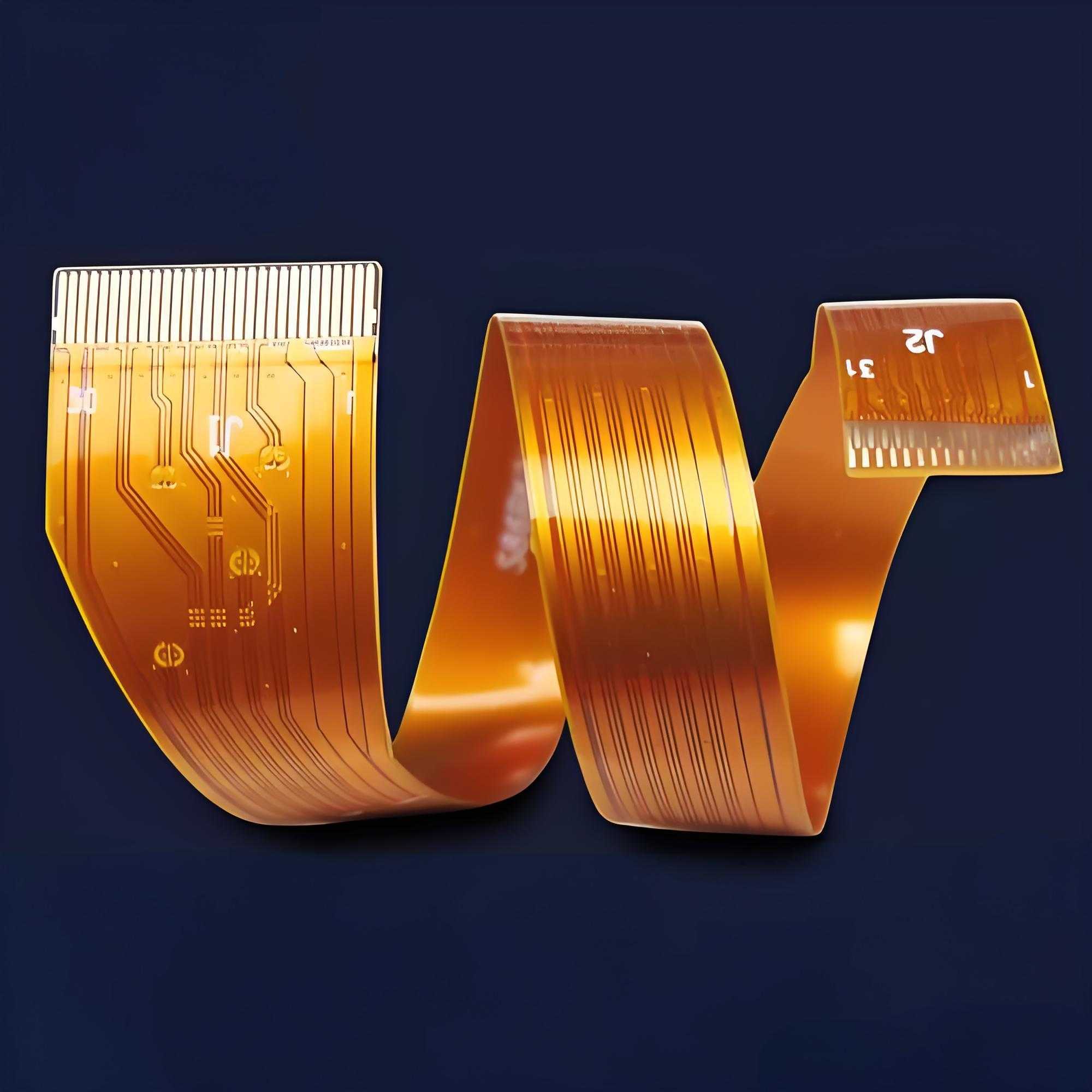

FPC refers to a flexible electronic circuit board. A flexible circuit board is a highly reliable and flexible printed circuit made of polyimide or polyester film as the base material. Abbreviated as flexible board or FPC, it features high wiring density, light weight, and thin thickness.

Flexible Electronic Circuit Board

FPC is mainly used in many products such as mobile phones, laptops, PDAs, digital cameras, LCMs, etc. Below, Coating Online introduces common related terms for FPC.

- Access Hole

An access hole refers to the holes made on the cover layer of the flexible circuit board, which serves as a solder mask. These holes are intentionally exposed to allow the connection points to be accessible for component soldering. Some multilayer boards also have these access holes.

- Acrylic

Commonly known as polymethyl methacrylate (PMMA), most flexible boards use acrylic films as adhesives.

- Adhesive

A material such as resin or coating used to bond two interfaces together.

- Anchoring Spurs

On single-sided or double-sided boards, additional anchor spurs are placed around the hole pads to strengthen the adhesion of the pad to the board surface and reduce the chance of it lifting off.

- Bandability

The bending capability of a flexible board. For example, the flexible board used in the print heads of computer disk drives must pass bending tests up to a billion cycles.

- Bonding Layer

Refers to the adhesive layer between the copper foil and the polyimide (PI) substrate in multilayer boards, TAB tapes, or flexible boards.

- Coverlay/Cover Coat

The protective layer applied on the outer layer of a flexible board. Due to the risk of delamination during bending, the coverlay is often made of flexible acrylic rather than the hard solder mask used for rigid boards.

- Dynamic Flex (FPC)

A flexible circuit board that is used for continuous movement, such as the flexible boards in disk drive heads. In contrast, static FPCs do not move after assembly.

- Film Adhesive

A dry film adhesive layer, which may include reinforced fiber or consist solely of adhesive material. Used as the bonding layer in FPCs.

- Flexible Printed Circuit (FPC)

A special type of circuit board that can change shape during assembly. Made of flexible polyimide (PI) or polyester (PE), it can have through-hole or surface-mount components, similar to rigid boards. It may also have a protective coverlay for solder masking.

- Flexural Failure

The failure of a material due to repeated bending or flexing, leading to cracking or breaking.

- Kapton

A DuPont product name for polyimide film, used as the base material in flexible circuit boards after being laminated with copper foil.

- Membrane Switch

A switch or keyboard made by printing silver paste onto a polyester (Mylar) film using screen printing techniques. Commonly used in devices like calculators, electronic dictionaries, and remote controls.

- Polyester Films

Abbreviated as PET films, commonly seen as DuPont’s Mylar Films. PET is a good insulating material and is used in the protective layers of FPCs.

- Polyimide (PI)

A high-performance resin made by polymerizing bismaleimide and aromatic diamine, first introduced by the French company Rhone-Poulenc as Kerimid 601. DuPont manufactures it as Kapton. PI has excellent heat and electrical resistance, making it a key material in FPCs and military applications.

- Reel to Reel

A process where electronic components, such as TAB, IC lead frames, or certain FPCs, are produced using reel-to-reel automation, improving production efficiency and reducing costs.

Gekun is a leader in the multilayer flexible printed circuit board market, providing high-quality solutions tailored to the needs of modern industries. With cutting-edge manufacturing facilities and a focus on innovation, Gekun offers FPCs that meet the most stringent industry standards. Their expertise in multilayer FPC manufacturing ensures that customers receive reliable, high-performance products suited for automotive, aerospace, and consumer electronics markets.

Gekun’s commitment to quality and precision makes them a trusted partner for businesses looking to innovate and stay ahead in the competitive market.

Gekun web https://gekunflex.com