1. FPC Brings New Transformations to New Energy Vehicles

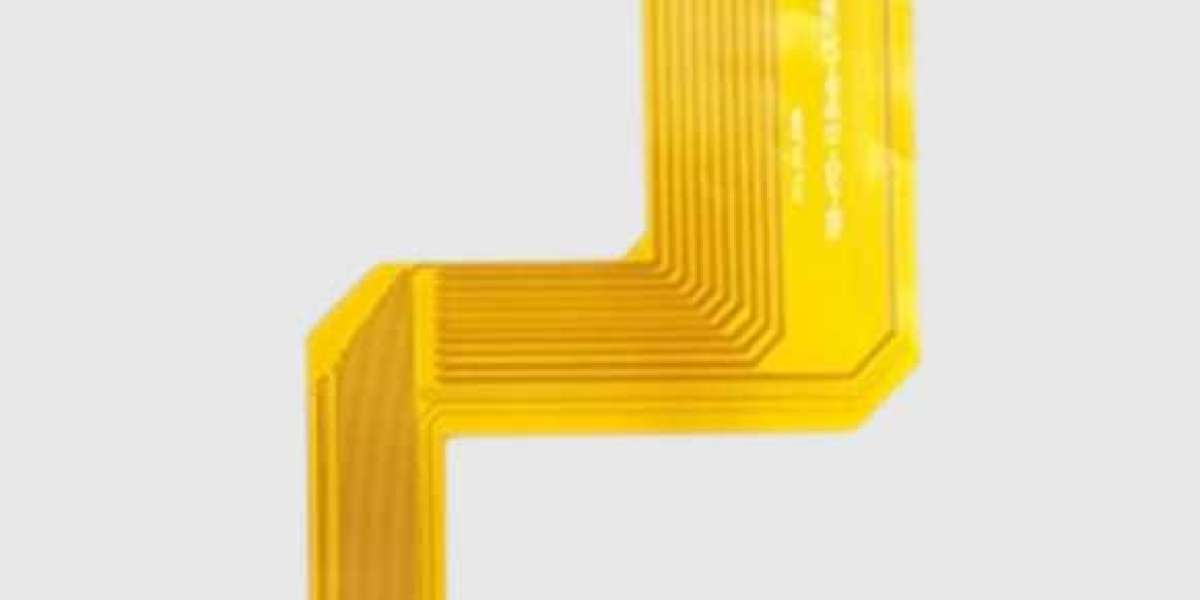

As new energy vehicles (NEVs) emerge as the future of the automotive industry, they are spearheading a revolution in transportation. Behind the scenes, the Flexible Printed Circuit (FPC) plays a crucial role in this transformation, acting as a silent hero.

(1) Enhancing Interior Space Utilization

The interior of NEVs is complex, with numerous electronic devices. The flexible nature of FPC allows it to fit into irregular shapes, making it ideal for routing in tight corners and on curved surfaces. For example, within the dashboard, FPC can follow intricate contours to connect various control modules and display screens, organizing previously cluttered wiring and greatly improving space utilization. This provides designers with more creative freedom, allowing for sleeker and more aesthetic interior layouts.

(2) Supporting Efficient and Stable Operation of Electronic Systems

In the electronic systems of NEVs, stable power supply and data transmission are critical. FPC offers excellent conductivity and signal transmission performance, effectively reducing signal attenuation and interference during transmission. In the battery management system, FPC monitors various parameters with precision, ensuring safe and efficient charging and discharging. In the onboard smart system, it swiftly transmits commands and data, enabling smooth and intelligent coordination between the electronic components, improving the overall driving experience.

(3) Adapting to Harsh Automotive Environments

NEVs face various challenging conditions, including high heat, extreme cold, vibrations, and humidity. FPC is designed with special materials and processes to withstand high temperatures, low temperatures, vibrations, and moisture. Whether on a hot desert road or in a freezing northern winter, FPC maintains stable performance, ensuring the safety and reliability of NEVs.

2. Deep Integration of FPC in Key Areas of NEVs

(1) Autonomous Driving

As autonomous driving technology evolves, sensors and cameras become the "eyes" of NEVs. FPC connects these sensors to the onboard computer, transmitting large amounts of image and data quickly and accurately to support autonomous driving algorithms. Its thin, flexible characteristics simplify wiring and reduce the risk of faults due to wiring issues, improving the reliability and stability of the autonomous driving system.

(2) Innovation in Power Systems

In the core power systems of NEVs, FPC is widely used in battery connections and motor control systems. It accurately monitors the battery's voltage, current, and temperature, ensuring balanced battery management, extending battery life, and optimizing motor control strategies. This increases power output efficiency while reducing energy consumption, providing NEVs with stronger and longer-lasting power.

(3) Upgrading the Smart Cockpit Experience

The smart cockpit is an essential aspect of enhancing the user experience in NEVs. FPC plays a key role in connecting devices like in-car displays, audio systems, and seat adjustment mechanisms. It ensures high-definition display, high-quality audio transmission, and comfortable seat adjustments, creating a comfortable, convenient, and intelligent driving environment for both the driver and passengers.

3. Choosing a Premium FPC Manufacturer – Gekun

In the FPC industry, Gekun stands out as a professional manufacturer with excellent technical expertise and extensive production experience.

(1) Advanced Production Technology

Gekun employs advanced production equipment and processes to ensure high-quality FPC manufacturing. Every step, from material selection to product testing, is rigorously controlled, ensuring the FPC's exceptional performance and stability. These FPCs meet the stringent requirements of NEVs in areas such as signal transmission, heat resistance, and vibration resistance.

(2) Customization Services

Gekun understands that different NEV manufacturers have diverse needs, so it offers customized FPC solutions. Based on vehicle models, functional requirements, and spatial layouts, Gekun tailors the most suitable FPC products, helping automotive manufacturers optimize designs, reduce costs, and improve production efficiency.

(3) Reliable Quality Assurance

Gekun boasts a comprehensive quality assurance system, with products undergoing strict testing and certification. Its FPCs have performed excellently in actual NEV applications, earning the trust and praise of numerous automotive manufacturers. Choosing Gekun’s FPC means choosing quality, reliability, and innovation. Whether for high-performance premium models or cost-effective mass-market vehicles, Gekun provides top-tier FPC products, fueling the growth of the NEV industry.

Gekun web,https://gekunflex.com