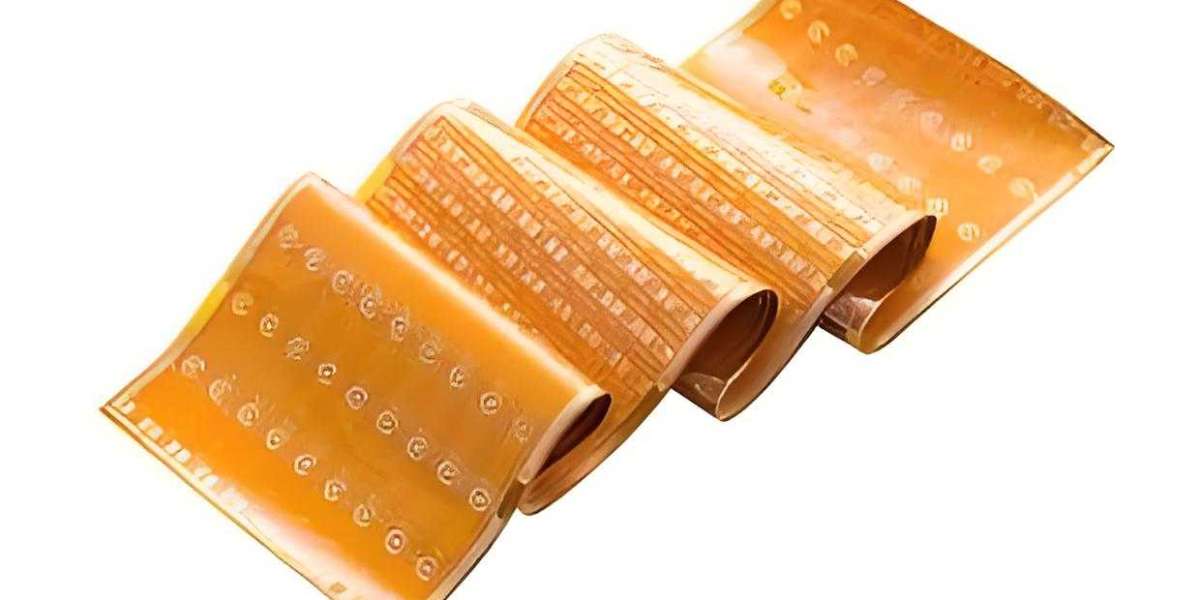

Flexible Printed Circuit (FPC) is a high-reliability and flexible printed circuit board made from polyimide or polyester film. It boasts several advantages such as high wiring density, light weight, thin thickness, and excellent flexibility. Today, let's explore the four most common types of flexible circuit boards.

1. Single-Sided Flexible Board

This is the lowest-cost option. When electrical performance requirements are not high and single-sided wiring is sufficient, a single-sided flexible board should be used. This is the most common type and has been widely commercialized in products like printer ink cartridges and computer memory. Single-sided flexible boards consist of a layer of chemically etched conductive patterns, where the conductive pattern layer on the surface of the flexible insulating substrate is made of rolled copper foil. The insulating substrate used for flexible assemblies can be polyimide (Kapton), polyethylene terephthalate (PET), aramid fiber paper (Nomex), or polyvinyl chloride (PVC).

2. Double-Sided Flexible Board

A double-sided flexible board is created by etching conductive patterns on both sides of the base film. Metallized holes connect the patterns on both sides of the insulating material, forming conductive pathways that meet the design and usage flexibility requirements. A cover layer can protect the single-sided and double-sided conductors and indicate the position of components.

3. Multilayer Flexible Board

A multilayer flexible board consists of three or more layers of single-sided or double-sided flexible circuits laminated together. Metallized holes are drilled and plated to form conductive pathways between different layers. This eliminates the need for complex welding processes. Although the number of conductive layers in this type of flexible circuit can be theoretically unlimited, it is essential to consider the balance between assembly size, number of layers, and flexibility during the design process for optimal assembly.

4. Rigid-Flex Combination

A traditional rigid-flex board is composed of rigid and flexible substrates selectively laminated together. The structure is compact, with metallized holes forming conductive connections. For reasons of reliability and cost, manufacturers should aim to keep the number of layers as low as possible.

HDI Rigid-Flex Board: High-Density Interconnect (HDI) rigid-flex printed circuit boards represent high-end PCB products. They are designed to meet the growing demand for miniaturization, high frequency, high speed, and multifunctionality in electronic products. The HDI rigid-flex board combines the advantages of popular HDI boards and traditional rigid-flex boards, promoting a high level of integration and intelligence in electronic system design and manufacturing. These boards are widely used in high-end electronics like aerospace, medical devices, and consumer products.

Why Choose Gekun?

Gekun is an outstanding flexible printed circuit board manufacturer in China. Here are some of its key strengths:

Extensive Experience: With over 10 years of experience in flexible circuit board manufacturing and design, Gekun has accumulated significant expertise and technical knowledge in the field.

Wide Range of Products: Gekun offers a diverse array of products, including flexible printed circuit boards, multilayer flexible circuit boards, rigid-flex boards, and PCB assembly, catering to the different needs of customers across various applications.

High-Quality Materials and Production: All materials used are A-grade, and electronic components are sourced directly from manufacturers. Gekun adheres strictly to the ISO 9001 quality management system, ensuring product consistency and stable quality.

Customized Solutions: Gekun provides customized production based on customer-supplied Gerber data. It also offers services like logo printing and packaging customization, while providing optimal solution suggestions for customers’ products.

Efficient Delivery Capability: Gekun can provide samples within 5 days and deliver bulk orders within 10-15 days, meeting customer demands for quick delivery times.

Wide Market Coverage: Gekun's products are used in a variety of industries, including telecommunications, computers, consumer electronics, automotive, medical, and industrial control. Its products are also exported to regions like Europe, Vietnam, India, and the United States.